Overview of Main PMMA Grades and Applications

Application Area | Recommended Grade (Supplier) | Key Characteristics |

General Injection Molding & Lighting | CM-205 (CHIMEI) | Good flowability, balanced performance |

Optical Display | 8N (Rohm) | High light transmission, low impurities |

Weather-Resistant Exterior | SX-306 (Double elephant) | Excellent UV resistance, high weatherability |

Automotive Components | XF-03 (Rohm) | Good heat resistance, high mechanical strength |

Medical Devices | HD01L (Wanhua) | Good biocompatibility, meets medical standards |

Characteristics and Applications of Each Grade

CHIMEI CM-205

Characteristics: High strength, good weather resistance, light transmission >92%.

Applications: Automotive signal lights, instrument panels, lighting equipment.

Rohm XF-03

Characteristics: Excellent mechanical and thermal properties, good flowability.

Applications: Injection-molded optical components, lighting and display parts.

Rohm 8N

Characteristics: Optical grade PMMA, ultra-high light transmission, extremely low impurities.

Applications: Display light guides, precision optical components.

Double elephant SX-304/SX-306

Characteristics: SX-304 high light transmission, SX-306 excellent weather resistance.

Applications: Construction panels, outdoor advertising signs.

Wanhua HD01L

Characteristics: Medical grade standards, good biocompatibility, strong chemical stability.

Applications: Medical device housings, laboratory utensils.

Material Selection Guide by Application Area

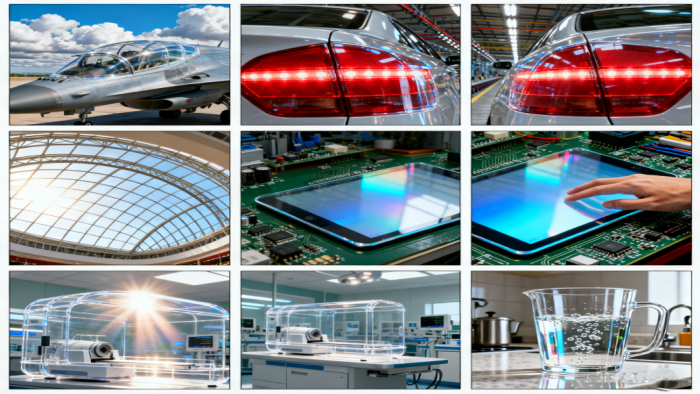

Automotive Industry

· Heat Resistance: Components near engine compartment - CHIMEI CM-205

· Weather Resistance: External components - Double elephant SX-306

· Optical Requirements: Lamp covers, optical parts - Rohm XF-03 and 8N

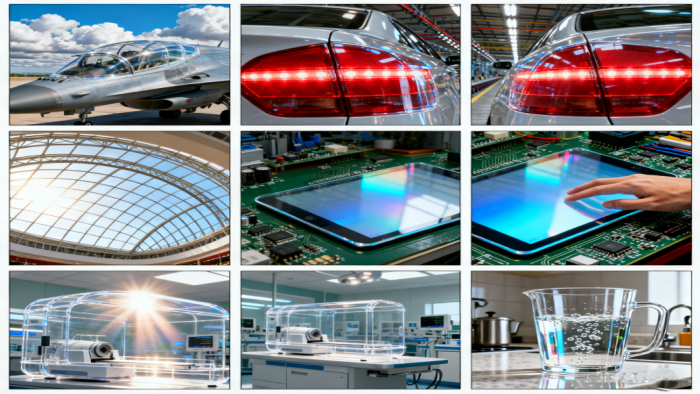

Optical Display

· Light Transmission: Must be >92% - Rohm 8N is best

· Impurity Control: Requires extremely low impurity content

Construction and Lighting

· Weather Resistance: Resists UV, rain, temperature changes - Double elephant SX-306

· Mechanical Strength: Strong impact and wind pressure resistance

Medical Devices

· Biocompatibility: Medical certification required - Wanhua HD01L

· Chemical Stability: Withstands disinfectants and cleaning agents

Key Selection Insight

There is no "universal" PMMA grade, only the "most suitable" choice for specific application scenarios. Successful material selection begins with accurate understanding of application requirements.

Typical Application Cases

Case: Automotive LED Taillight Project

Requirements: Heat resistance above 95掳C, excellent weather resistance, automotive standards

Material Selection: CHIMEI CM-205 (high heat resistance), Rohm XF-03 (good processability)

Result: Selected CHIMEI CM-205, passed customer acceptance

Case: High-end TV Light Guide Plate

Requirements: Light transmission >93%, extremely low impurities, excellent optical uniformity

Material Selection: Rohm 8N (optical grade), Double elephant SX-304 (high purity)

Result: Selected Rohm 8N, product brightness increased by 15%

Conclusion

PMMA material selection is a systematic decision-making process requiring comprehensive consideration of technical performance, processing characteristics, cost-effectiveness and supply chain stability.

Contact Us

English

English