In the manufacture of medical devices and packaging, the selection of the right polymer is paramount to ensuring patient safety, product efficacy, and regulatory compliance. Polypropylene (PP) remains a material of choice due to its versatility, chemical resistance, and sterilizability. This article provides a technical overview of select high-performance medical-grade PP resins from leading global suppliers like LyondellBasell and Hyosung, and explains how we, as a specialist distributor with in-house compounding capabilities, can support your projects from standard grades to fully customized solutions.

Part 1: Premium Medical PP Grades – Performance Data and Applications

We partner with top-tier producers to ensure a reliable supply of certified medical-grade PP. Below is an analysis of key grades based on their technical datasheets.

High Clarity & Flow for Disposables (Syringes, Pipette Tips, Vials)

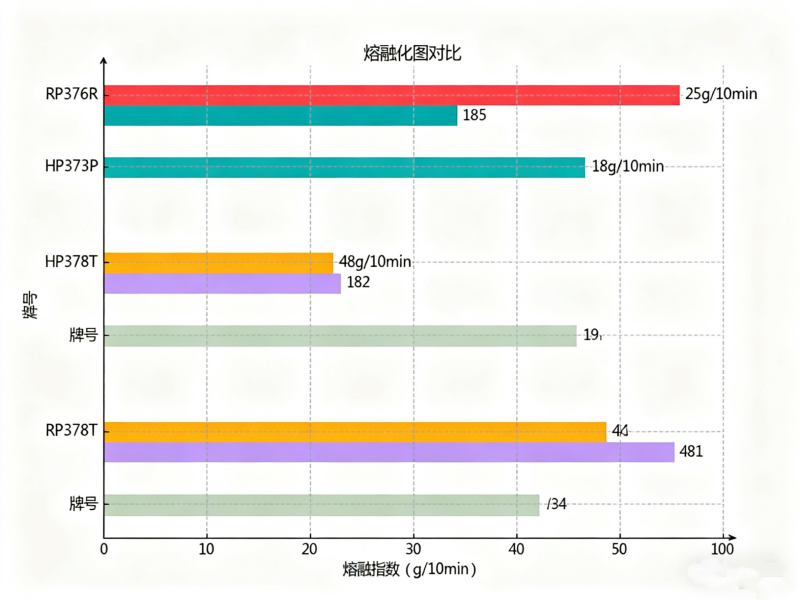

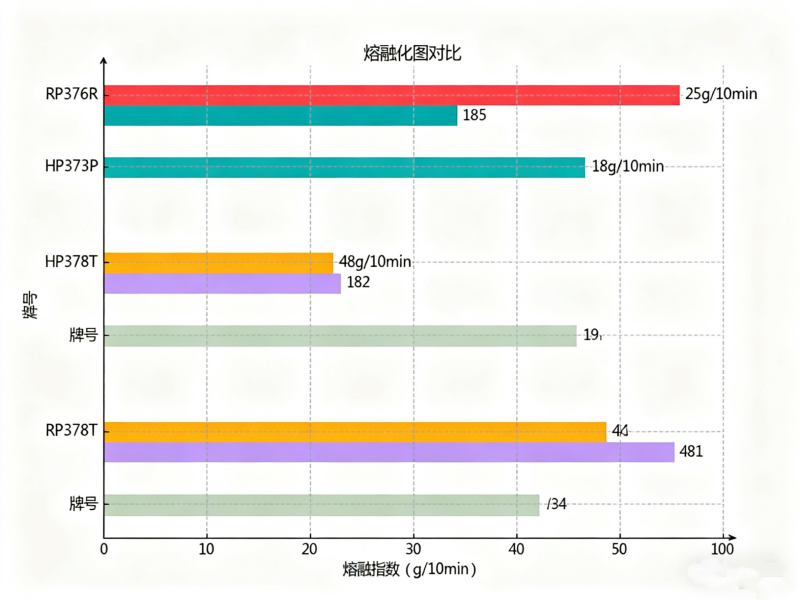

LyondellBasell RP376R: This random copolymer offers an excellent balance of high clarity (Haze: 9.5%) and high melt flow rate (MFR: 25 g/10min), facilitating easy processing for thin-walled components. It complies with USP Class VI and has a Drug Master File (DMF 36411), making it ideal for diagnostic equipment, PCR tubes, and disposable syringes.

LyondellBasell RP378T: Featuring a very high MFR (48 g/10min) and high clarity, this grade is designed for high-productivity injection molding of complex thin-walled devices.

Hyosung R530A / R530: These grades provide excellent transparency and comply with stringent regulations including FDA 21 CFR 177.1520, EU 10/2011, and USP Class VI. They are well-suited for intravenous (IV) bottles, pharmaceutical applications, and food contact containers.

Superior Sterilization Resistance (Reusable Trays, Labware)

LyondellBasell PF531: This homopolymer is stabilized against gamma radiation, maintaining color and physical properties post-sterilization. With an MFR of 27 g/10min, it processes easily for labware and healthcare products.

LyondellBasell HP373P: A versatile homopolymer with good flow (MFR: 18 g/10min) and compatibility with multiple sterilization methods, including autoclave, Ethylene Oxide (EO), and E-beam.

LyondellBasell HP570R: Exhibiting excellent resistance to moist heat sterilization (Vicat Softening Temperature: 154°C), this grade is perfect for caps, closures, and diagnostic products requiring repeated autoclaving.

Specialized Performance (High Stiffness, Impact, Antistatic)

LyondellBasell PP702N (PD702NW): An antistatic grade with high stiffness (Flexural Modulus: 1380 MPa), ideal for medical containers, shields, and housings where dust attraction is a concern.

LyondellBasell RP270G: An impact-modified random copolymer with good low-temperature toughness and chemical resistance, suitable for flexible packaging like IV bags and medical films.

LyondellBasell RP271M: This grade balances high impact strength with heat resistance, making it applicable for Injection Stretch Blow Molding (ISBM) of sterilizable containers.

Part 2: Beyond Distribution: Value-Added Compounding and Support

Our expertise extends beyond supplying standard grades. Our in-house compounding plant allows us to add significant value.

Technical Collaboration: Our engineers can help you interpret datasheets and select the optimal base resin for your specific sterilization, mechanical, and regulatory needs.

Custom Compounding Services: We modify premium base resins to achieve:

Color Masterbatches: Using medically safe pigments.

Property Enhancement: Tailoring impact strength, adding antimicrobial properties, or adjusting flame retardancy.

Regulatory Compliance Support: Ensuring modified compounds meet necessary international standards.

Conclusion and Call to Action

Selecting the right medical PP is a critical decision that impacts your product's time to market and regulatory success. We combine a portfolio of world-class resins with deep technical expertise and custom compounding capabilities to be your ideal partner.

For detailed Technical Data Sheets (TDS) on any of these grades or to discuss a custom compounding project, please contact our technical sales team. Let's engineer the perfect material solution for your medical device.

[Contact Our Technical Experts] / [Request a Free Sample]

English

English