Selecting the right polycarbonate material is critical for achieving optimal performance in injection molding applications. This technical comparison provides engineers and product designers with detailed insights into two premium PC materials: Mitsubishi's IUPILON™ S-3000VR and Teijin's PANLITE® L-1225Y.

Comprehensive Performance Analysis:

Our laboratory data reveals significant differences in key performance areas:

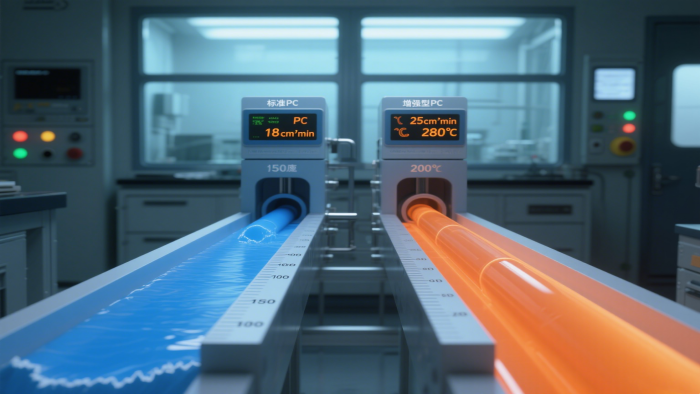

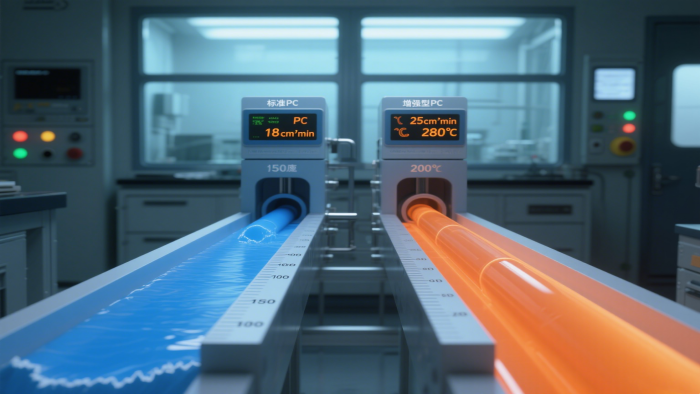

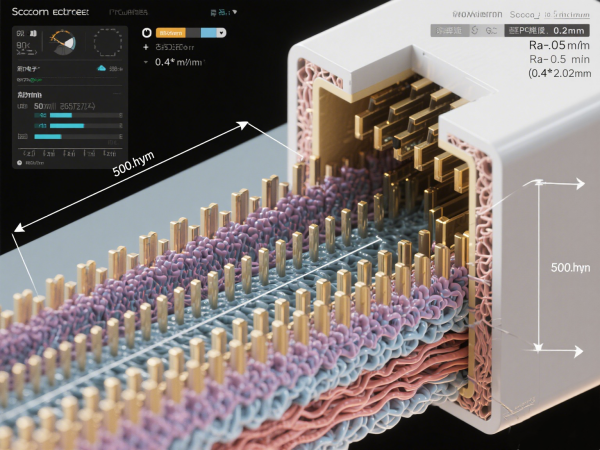

1. Melt Flow Characteristics:

S-3000VR demonstrates superior flowability with 15g/10min melt flow rate, making it ideal for complex thin-wall designs and multi-cavity molds. This high-flow characteristic reduces injection pressure requirements and improves filling performance in intricate geometries.

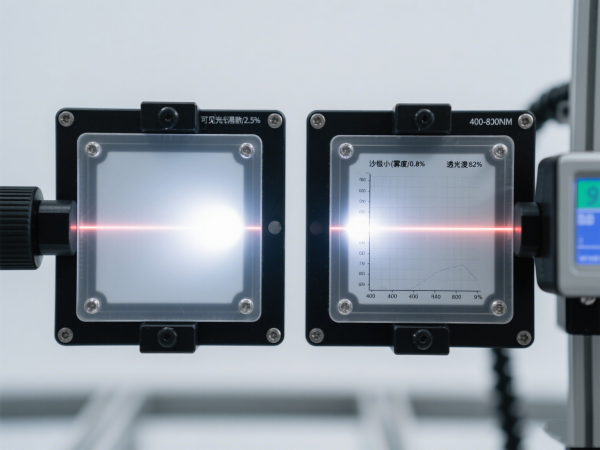

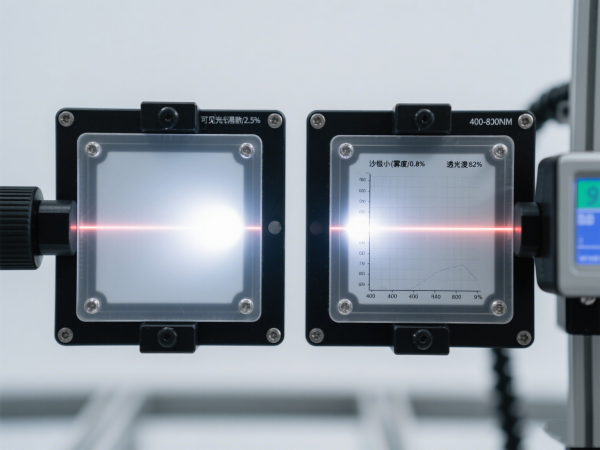

2. Optical Properties Evaluation:

L-1225Y excels in optical applications with 88% light transmittance and excellent clarity retention. Its consistent refractive index (1.585) makes it suitable for precision optical components and automotive lighting systems requiring superior visual characteristics.

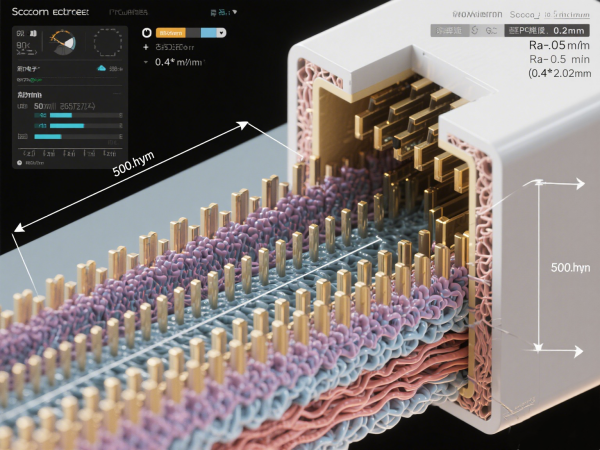

3. Mechanical Performance Comparison:

While both materials show excellent mechanical properties, L-1225Y offers marginally better impact resistance (71kJ/m² vs 67kJ/m²). Both maintain comparable tensile strength and flexural modulus, ensuring reliability in demanding structural applications.

4. Thermal Stability Assessment:

The materials exhibit similar Vicat softening temperatures (148°C) and heat deflection properties, providing consistent performance across various operating temperature ranges.

Application-Specific Recommendations:

Based on our technical analysis:

· Choose S-3000VR for:

High-precision electronic components requiring excellent flow characteristics

Complex structural parts with thin-wall sections

Applications demanding rapid cycle times and improved productivity

· Select L-1225Y for:

Automotive lighting systems and transparent components

Medical device windows and protective shields

Applications requiring GM QK005931 compliance and optical clarity

Processing Optimization Insights:

Our two decades of compounding experience recommend:

· Optimize injection parameters to leverage S-3000VR's flow properties

· Use polished molds to maximize L-1225Y's optical performance

· Implement strict drying protocols (120°C, 4-8 hours) for both materials

CTA:

Email us today with your quantity and destination for a prompt quotation. Visit our product page to download the datasheet and request a sample.

[Contact Our Technical Experts] / [Request a Free Sample]

English

English