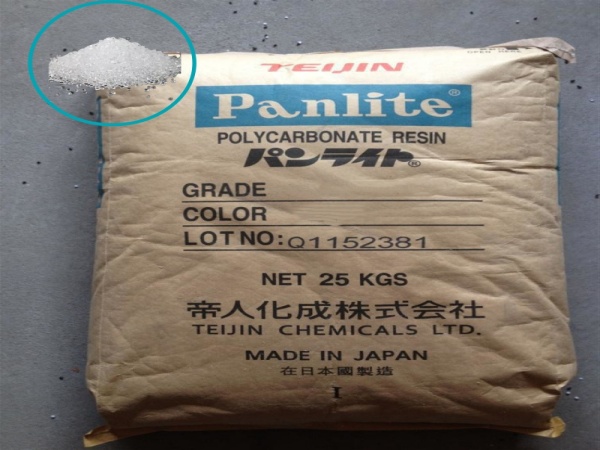

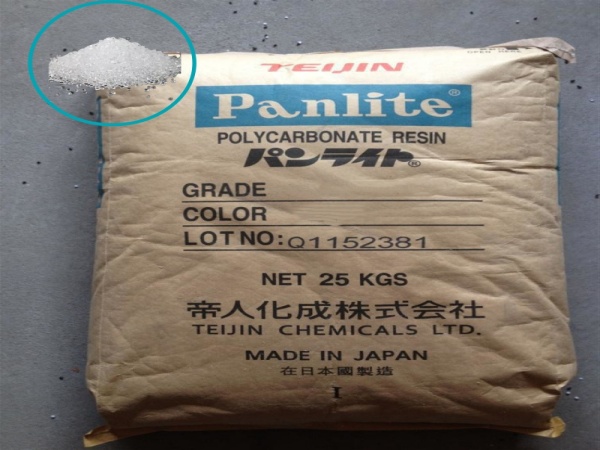

For Euro-American home appliance and consumer electronics manufacturers, compliance with strict international standards, production efficiency and product durability are non-negotiable. TEIJIN’s PANLITE® PC L-1225L emerges as a trusted injection molding material, perfectly aligning with the high-end technical demands of these markets. Combined with our professional capabilities, it empowers enterprises to optimize production and gain competitive edges.

1. Technical Advantages: Meeting Euro-American Strict Standards

PANLITE® PC L-1225L’s key indicators fully comply with ISO/ASTM/UL standards, ensuring seamless integration into local production systems:

Ultra-low Viscosity for Efficiency: With a melt volume flow rate of 18.0 cm³/10min (300°C/1.2kg, ISO 1133), it enables smooth filling of thin-walled (0.4-1.5mm) and complex molds, critical for miniaturized electronics. The 0.50-0.70% shrinkage rate (4.0mm) guarantees dimensional stability, reducing defect rates.

UL94 V-2 Flame Retardancy: Achieving UL94 V-2 grade (0.4mm thickness) and HB grade (1.9mm thickness), it meets EU RoHS and US fire safety requirements, eliminating risks in electrical components like charger housings and control panels.

Comprehensive Performance: Boasting 61.0 MPa tensile strength (ISO 527-2/50) and 67 kJ/m² notched Izod impact strength (ISO 179), it ensures product durability. The 139°C heat distortion temperature (0.45MPa, ISO 75-2/B) and 88.0% light transmittance (ASTM D1003) make it suitable for both high-temperature appliances and transparent components.

2. Targeted Applications in Euro-American Markets

The material has been widely adopted by leading brands across regions:

Home Appliances: German microwave manufacturers use it for control panels, leveraging its flame retardancy and insulation (volume resistivity 1E+15 Ω.cm, IEC 60093) to meet CE certification. US rice cooker brands select it for transparent windows, benefiting from its heat resistance and clarity.

Consumer Electronics: European smartphone brands apply it to charger housings, with its excellent flowability optimizing complex structure molding. US TWS earphone makers rely on its low shrinkage and impact resistance to enhance product reliability.

3. Our Support for Global Partners

We provide one-stop solutions tailored to Euro-American customers:

Genuine Supply Chain: Long-term cooperation with TEIJIN’s official distributors ensures 100% authentic products with complete certifications (MSDS, UL reports) for smooth customs clearance.

Customized Modification: Offer heat resistance enhancement (HDT up to 170°C) and UV resistance modifications, compliant with IATF16949 standards.

Professional Technical Support: 24/7 online consultation on molding parameters and sample testing, helping shorten trial production cycles.

Contact us for quotes or technical advice:

WhatsApp: +86 151 9251 3751 (Note "TEIJIN L-1225L")

Email:may@qdmfmy.com (Note "TEIJIN L-1225L")

English

English