Before discussing specific applications, it's important to understand why PMMA stands out among transparent materials:

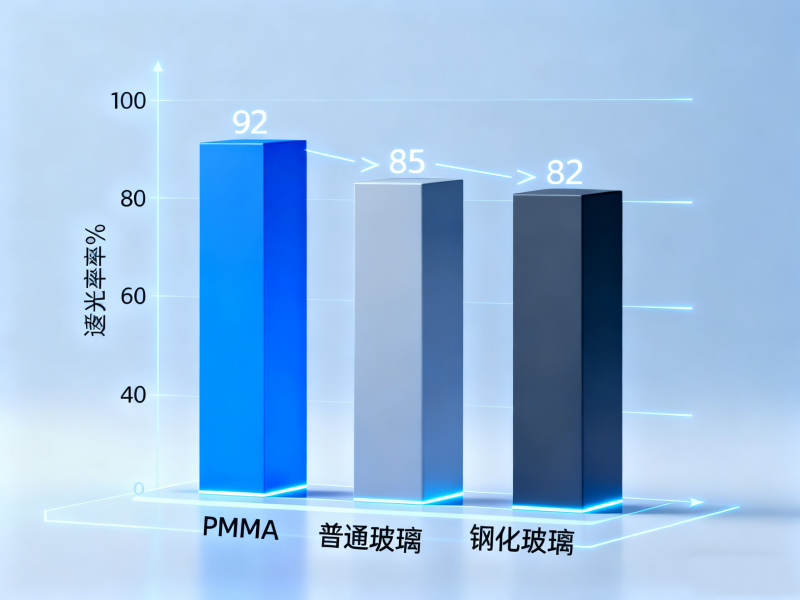

Exceptional light transmittance: Up to 92%, outperforming ordinary glass and most other transparent plastics

Excellent surface hardness: Outstanding scratch resistance maintains product aesthetics

Superior weather resistance: Resists yellowing and degradation during long-term outdoor use

Good processability: Suitable for various molding processes including injection and extrusion

Safety and environmental friendliness: Recyclable, meeting modern environmental requirements

Differentiated PMMA Applications Across Industries

1. Automotive Industry: Balancing Safety and Aesthetics

In the automotive sector, PMMA is used not only for taillight covers but also extensively for instrument panel covers, window triangular areas, and interior components. These applications place strict requirements on the material's heat resistance, UV resistance, and chemical corrosion resistance. Automotive-grade PMMA typically requires special modification to withstand temperature variations from -40°C to 80°C.

2. Construction Industry: Combining Function and Aesthetics

Construction-grade PMMA panels are commonly used for skylights, noise barriers, and decorative panels. Unlike standard PMMA, construction-grade products require higher impact strength and flame retardancy levels. We previously customized UV-resistant and impact-modified PMMA panels for a commercial center project, significantly improving safety performance while maintaining light transmittance.

3. Optics and Display: Pursuing Ultimate Purity

In fields such as optical lenses, light guides, and display diffusion films, PMMA's purity, light transmittance, and optical uniformity are crucial. These applications require "optical-grade" PMMA with extremely strict standards for impurity content and haze index. A tiny bubble or impurity can render an entire batch of products unusable.

4. Lighting Industry: Balancing Heat Dissipation and Weather Resistance

LED covers, light tubes, and fixture housings represent another important application area for PMMA. This requires balancing light transmittance with diffusion effects while considering the material's heat resistance and UV stability. Our specially developed light-diffusing PMMA evenly softens light while withstanding heat generated by LED chips.

5. Medical and Sanitary: Prioritizing Safety and Hygiene

Applications such as medical device observation windows, test tube racks, and sanitary partitions place special requirements on PMMA's biocompatibility, chemical resistance, and impact strength. Medical-grade PMMA must pass relevant certifications to ensure it doesn't release harmful substances.

Industry Insight: Why One PMMA Doesn't Fit All Applications

Different industries have vastly different performance requirements for PMMA. For instance, the construction industry focuses on impact resistance and weather resistance, the optical industry pursues ultimate light transmittance, while the medical sector prioritizes biosafety. Choosing the wrong PMMA grade can lead to substandard product performance or even safety issues. Professional plastic suppliers can recommend the most suitable PMMA type or provide custom modification solutions based on your specific application scenario.

Get Professional Material Solutions

As specialists in plastic raw materials and modification services, we offer various PMMA grades and custom modification solutions. Whether you need standard types or custom solutions with specific properties, we can provide expert support.

Conclusion

PMMA serves as an excellent transparent material across various industries. However, "acrylic" isn't a universal solution - different applications require PMMA products with different specifications and properties. By deeply understanding specific industry requirements and collaborating with professional material suppliers, you can select the most appropriate PMMA material for your product, optimizing performance while controlling costs.

Choosing the right material is the first step toward product success. We hope this article helps you better understand PMMA application nuances, enabling wiser material choices for your next project.

English

English