The Fogging Challenge: A Global Design Obstacle

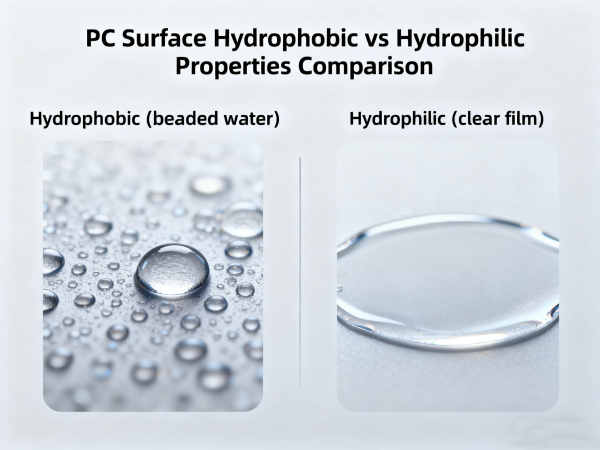

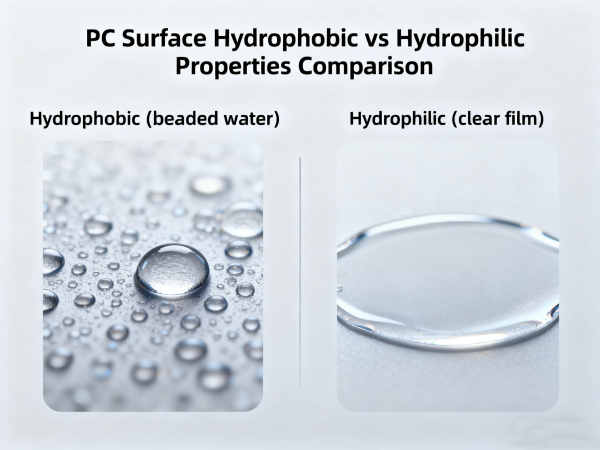

Fogging on transparent components is a critical failure point in medical devices, automotive sensors, and premium packaging. Standard PC, being hydrophobic, exacerbates this issue. The engineered solution is Hydrophilic Polycarbonate.

What is Hydrophilic Polycarbonate?

It is a specially modified PC that transforms surface properties from water-repelling (hydrophobic) to water-attracting (hydrophilic). This allows moisture to form an invisible, continuous film instead of light-scattering droplets, ensuring persistent anti-fog performance while maintaining the inherent clarity, strength, and flame retardancy of PC.

Your 2025 Sourcing Checklist: How to Choose?

1. Performance First: Prioritize anti-fog efficacy, transparency (>88%), and mechanical integrity (Tensile Strength >60 MPa).

2. Safety Compliance: For electronics and medical applications, UL94 V-2/HB rating is often mandatory.

3. Processing Fit: Match the melt flow rate (e.g., 8-10 cm³/10min) to your injection molding or extrusion process.

4. Global Standards: Ensure compliance with international regulations like RoHS and UL for seamless market access.

Head-to-Head: Premier Hydrophilic PC Grades

Covestro Makrolon® 2805: The injection molding benchmark. Medium viscosity, excellent release properties, and superior mechanical strength (97 MPa flexural strength) make it ideal for precision parts.

Teijin PANLITE® L-1250Y: Versatile for both injection and extrusion. Offers broad UL certification and excellent processability for diverse applications.

Beyond supplying these premier grades, our in-house modification plant can tailor hydrophilic PC to your exact requirements—enhancing anti-fog longevity or matching specific colors.

Why Partner with Us? A Legacy of Reliability

We are more than a distributor; we are your strategic supply chain partner.

Expert Modification: 20+ years of expertise in engineering plastics modification.

Supply Chain Stability: Strong partnerships with top-tier producers ensure material availability.

Cost-Effectiveness: Competitive pricing achieved through volume procurement and integrated modification.

Global Service Network: Trusted by 200+ clients worldwide for consistent quality and reliable delivery.

CTA:

Ready to eliminate fogging in your 2025 products? Contact us today for a free consultation and sample kit of Makrolon® 2805 and PANLITE® L-1250Y. Our technical experts will help you make the optimal material choice.

Email us today with your quantity and destination for a prompt quotation. Visit our product

page to download the datasheet and request a sample.

[Contact Our Technical Experts] / [Request a Free Sample]

Don't miss out on experiencing the exceptional quality of PMMA SX-304.

English

English